At the heart of any supply chain strategy is a global view but you also need to understand data at a local level too. This requires integration across the journey. Without visibility, challenges can’t be pinpointed and improvements – such as optimising stock levels or selecting alternative logistics partners – can’t be made. A strategy which will guide the flow of services from the point of creation to customer receipt can revolve around four factors: demand planning, rapid planning and integration, sustainability and efficiency. Successful management of supply chains means optimising people, processes and products to minimise business costs and maximise business output and profits. It’s simply an exercise in efficiency and if there’s one thing that Enterprise Resource Planning (ERP) solutions are all about, it’s improving productivity. If there’s one thing BrightBridge is about, it’s ERP solutions.

Here we take a look at a number of ways how a retail and wholesale distribution business can improve its supply chains to improve the bottom line and also dispense with delays and dissatisfied customers. Read on to learn more about the benefits of having complete global visibility when managing products through procurement, receiving, warehousing, packing, shipping and delivery.

Choosing the right strategy

It’s likely that the primary focus will be around customer expectations. For example, a luxury fashion brand like our customer RIXO may prioritise the manufacturing element and high-quality fabrics while a company like our customers Misco and Comet may prioritise product availability and fast standard delivery. When selling online and through resellers, two-way fulfilment and returns procedures need to be factored in and automation helps to speed up warehouse and inventory management processes.

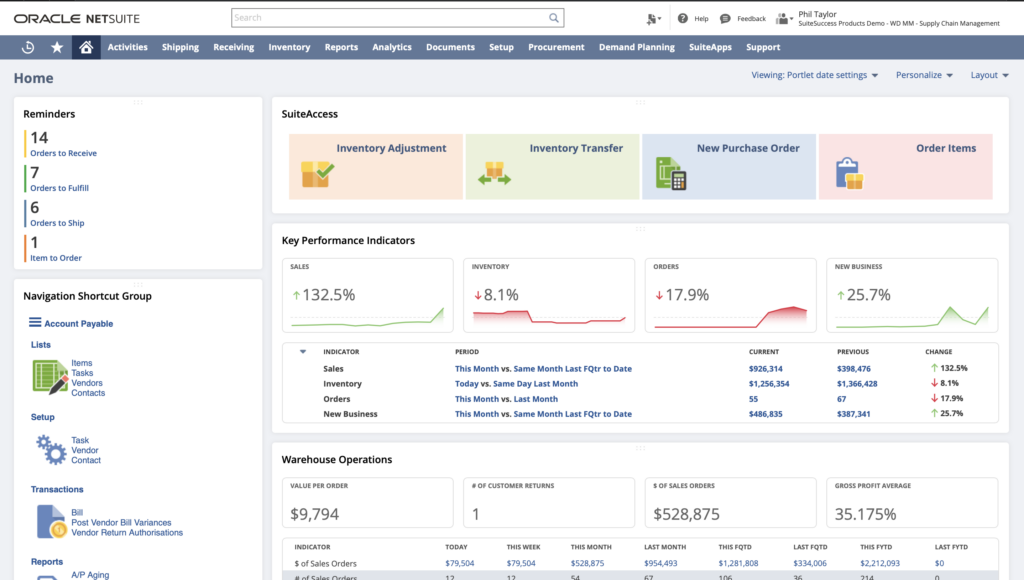

Tracking success through clear KPIs is important whatever the strategy and goals. The electronics retailer may aim to cut delivery times while the fashion brand may focus on reducing out of season stock. By setting clear, measurable goals, retailers and their partners can work collaboratively towards ensuring a smooth supply chain, plus each party is accountable for their performance.

Investing in the right technology

Software that gives a business visibility and control over inventory levels and insight into customer demand facilitates agile and lean operations. Cloud solutions manage enormous amounts of real-time, integrated data from all processes and departments in the supply chain and essentially provide the intelligence needed to make informed decisions. Big data analysis processes billions of data points to understand the best ways to optimise processes; automation of these processes provides further layers of efficiency and Artificial Intelligence (AI) can also be utilised to analyse data to obtain smart predictions and suggestions.

For example, effective demand forecasting functionality in an ERP solution ensures a business never has to deal with overstocking challenges – and the resulting storage expenses – and always has enough stock to take advantage of every sales opportunity. From forecasting customer demand to highlighting potential process hold-ups, the right supply chain technology will help wholesale distributors and retailers to be responsive, be prepared to adapt and be ready for any potential setbacks.

Tagging and tracking products

Tracking products through every step of the supply chain journey is one of the most effective ways of assessing efficiency and uncovering issues. Source tagging a product from the manufacturing plant and warehouse through to the time of purchase tracks the product’s exact location using a smart label or barcode. Warehouse automation functionality within cloud software, such as Oracle NetSuite, will record the location and movement of inventory, and negate the need for time-consuming manual counts. It handles the movement of products in and out of a warehouse, helping to reduce errors and process items more quickly. At the physical end of the automation scale, autonomous robots may be used to move heavy packages to exactly where they need to be, reducing labour-intensive work for team members.

Tracking with source tagging also means that retail staff will be alerted if someone tries to steal a product from a shop and radio frequency identification (RFID) is also often used too, which uses electromagnetic fields to monitor inventory and prevent theft. Newer tagging systems, provide real-time visibility into inventory throughout the supply chain, as well as access to data on customer demand. Crucial if a business needs to know the exact volume of products available to sell online at any given moment or the number of products needed to restock shelves in a brick-and-mortar location.

Being ready for returns

The rise of online shopping has brought with it a greater reverse logistics challenge; customers now not only change their mind on items, but in some sectors, multiple items and sizes are frequently ordered when only one item is required. It’s a complex process which includes providing return labels with items that are delivered or collected in store, shipping replacement products and inspecting returned items for re-sale. Returns may also come direct, need collecting from customers or could be returned via stores or drop-shipment locations. As customer loyalty and advocacy is at a premium these days, a smooth reverse logistics process and the right technology to facilitate this is a must for many retailers.

Communicating and collaborating

Every company in the supply chain will be managing its own priorities, but essentially, they should all be working towards the same goal. Collaboration is required for success and each party can provide insights that will help towards improving the whole supply chain. When a business understands the needs of stakeholders throughout the supply chain, it gets a more complete picture of how performance can improve for every department involved in the chain. When combined, these insights can lead to greater supply chain output, at reduced cost.

One-team working is also important internally as the retail or wholesale distribution supply chain touches multiple business departments, from marketing, to sales, to procurement. Key insights that are gathered by marketing and sales departments about customer behaviour help supply chain teams meet customer demand. When customers have expressed an interest in a new product or even pre-ordered, they will expect no hold ups after launch – collaboration helps to satisfy customer expectations.

Enterprise Resource Planning (ERP) solutions and supply chain improvement

ERP solutions are made up of modules that serve different functions and departments but are a single architecture, meaning all data is integrated. Processes – for the supply chain and everything else – work intelligently, end-to-end and with true cloud software, such as Oracle NetSuite, visibility is global and in real-time. NetSuite for Retail helps businesses meet customers’ needs across every sales and fulfilment channel while NetSuite Supply Chain Management keeps production and delivery schedules running smoothly and NetSuite Inventory Management automates and manages the tracking of products. With procurement features integrated, retailers and wholesale distributors can easily communicate with suppliers to ensure that shipments are accurate and on time.

If you’d like to speak to one of our NetSuite experts about increasing your profitability, improving your cash flow and reducing the supply chain risks your business is facing, please complete our call back form and we’ll be in touch.

Keep reading

What is a NetSuite implementation partner? How do you choose one?

Technology fit for total customer service in 2024

Ditching Sage 1000: what you need to know from businesses that have done it

6 ways AI-ready Microsoft Dynamics 365 helps chartered associations serve members

6 retail and wholesale distribution challenges and how NetSuite solves them

The most exciting features in Microsoft Dynamics 365 2023 Release Wave 2

How to manage a new NetSuite Release: one expert's update process

What’s in NetSuite Release 2023.2?